What do we do?

We offer custom made solutions, adaptes to our client’s needs.

ANTI-WRINKLES RUBBER BELTS

COMPENSATING ROLLERS

BRAKE SPARE PARTS

BLADE SPARE PARTS FOR LONGITUDINAL SLITTERS

ANTI-WRINKLES RUBBER BELTS

The aim of these rubber belts is to remove wrinkles formed along any process in which laminated rolled materials are used. They are placed on the already existing rollers, preventing wrinkles and fold formation.

Each rubber belt is custom made. In order to manufacture each belt, we take into account the following information:

• Roller dimensions (diameter and width)

• Distance between the rollers

• Wrap angle of the material over the roller.

• Chemicals that could get in contact with the rubber band.

• Temperature during the process.

• Roller dimensions (diameter and width)

• Distance between the rollers

• Wrap angle of the material over the roller.

• Chemicals that could get in contact with the rubber band.

• Temperature during the process.

ANTI-WRINKLES RUBBER BELTS

Once the belts are set in place, performance is immediate. Our belts are an affordable solution because they are set up on the already existing roller; there is no need to replace it. Also, no special abilities are needed to set the belts in place.

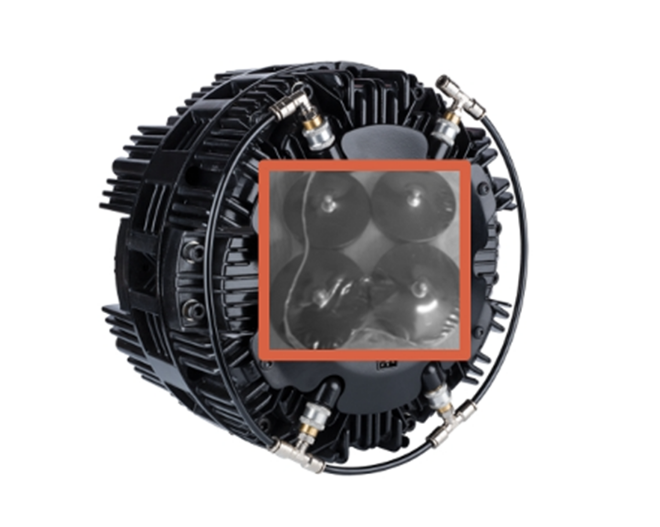

COMPENSATING ROLLERS

Compensating rollers readjust and correct any irregularity on the laminated material, at any point in the production line. Such irregularities can be due to alignment errors, material weight, thickness, width, length, etc…

It distributes the tension evenly throughout the band’s width. This maximizes the material’s resistance, specially at the start up point, preventing unwanted breakage or having to stop the machine. The main aim is preventing wrinkle formation and creasing.

COMPENSATING ROLLERS

Compensating rollers are particularly effective when placed before the cutting area, the gluing area or the temperature transmission area.

Compensating rollers are very functional, since they work automatically without any electric or electronic device added. Furthermore, its design allows the compensating rollers to be placed in any position. The static shaft, as well as the compensating mechanism are located inside the roller.

It is a very precise device, which is rather simple to adjust.

Compatible with Cantilever.

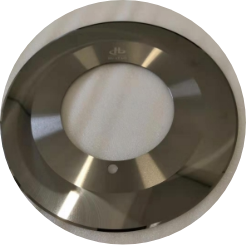

BRAKE SPARE PARTS

We market RE brake discs at a special price.

15€

per unit.

per unit.

Blade spare parts for longitudinal slitters

We market tungsten carbide blades for longitudinal slitters used in the production of corrugated cardboard.

First-class quality Materials are used to manufacture our blades; this guarantees sharp cuts on corrugated cardboard.

Blade spare parts for longitudinal slitters

Our blades are compatible with different types of machines:

- BHS

- TCY

- MARQUIP

- AGNATI

- FOSBER